Vancouver, BC – January 11, 2024 – American Pacific Mining Corp (CSE: USGD) (OTCQX: USGDF) (FWB: 1QC) (“American Pacific” or the “Company”) is pleased to report the third and final batch of assay results from the 2023 resource definition and geotechnical drill programs at the Palmer Project (“ Palmer ” or the “ Project ”). Palmer is an advanced-stage, high-grade volcanogenic massive sulphide-sulphate deposit (“ VMS ”) located in the Porcupine Mining District of the Haines Borough, Alaska, USA. Constantine North Inc., a subsidiary of American Pacific, is the operator for the Project and the ~US$20 million 2023 program was funded by joint venture (“ JV ”) partner Dowa Metals & Mining Co., Ltd (“ Dowa ”).

The final batch of 2023 assay results include the four (4) most significant copper (“Cu”) drill intersections (grade x thickness) reported to-date at Palmer , with significant zinc (“Zn”), gold (“Au”) and silver (“Ag”) results, as well as extending Cu-Zn mineralization beyond the current mineral resource estimate (“MRE”).

Highlights include :

- CMR23-172 Zone 1: 43.8 m grading 6.54% Cu, 3.15% Zn, 0.42 g/t Au and 27.97 g/t Ag (8.22% CuEq)

- CMR23-167 Zone 1: 37.1 m grading 4.57% Cu, 8.44% Zn, 0.50 g/t Au and 29.33 g/t Ag (8.40% CuEq)

- CMR23-169 Zone 1: 33.2 m grading 5.48% Cu, 7.22% Zn, 0.64 g/t Au and 36.78 g/t Ag (8.95% CuEq)

- CMR23-171 Zone 1: 23.9 m grading 9.03% Cu, 3.49% Zn, 0.83 g/t Au and 41.75 g/t Ag (11.15% CuEq)

- CMR23-168 Zone 1: 28.4 m grading 2.29% Cu, 4.01% Zn, 0.21 g/t Au and 26.61 g/t Ag (4.20% CuEq)

- CMR23-174 Zone 2-3: 39.8 m grading 1.11% Cu, 4.34% Zn, 0.45 g/t Au and 32.45 g/t Ag (3.31% CuEq) , including 17.8 m grading 1.05% Cu, 8.86% Zn, 0.94 g/t Au and 66.24 g/t Ag (5.54% CuEq)

Notes: Copper equivalents (“CuEq”) calculated using the same metal prices and recovery assumptions as the Company’s NI 43-101 Technical Report (JDS 2022). See Tables 1-3 for all new assay results and corresponding disclosure notes (metres = m).

“The final assay results from Palmer’s 2023 resource definition drilling have exceeded expectations with tremendous copper grades and aggregate metals values over significant widths,” commented Peter Mercer, Senior Vice President, Advanced Projects. “ Last year’s drilling has extended the mineralized envelope beyond the current MRE and our team is updating our 3D geological model. Preliminary interpretations have highlighted several priority target areas for follow-up drilling in 2024. In addition, the knowledge gained from this year’s drilling will provide valuable insights as we re-evaluate and rank the numerous VMS showings throughout the mineralized district.”

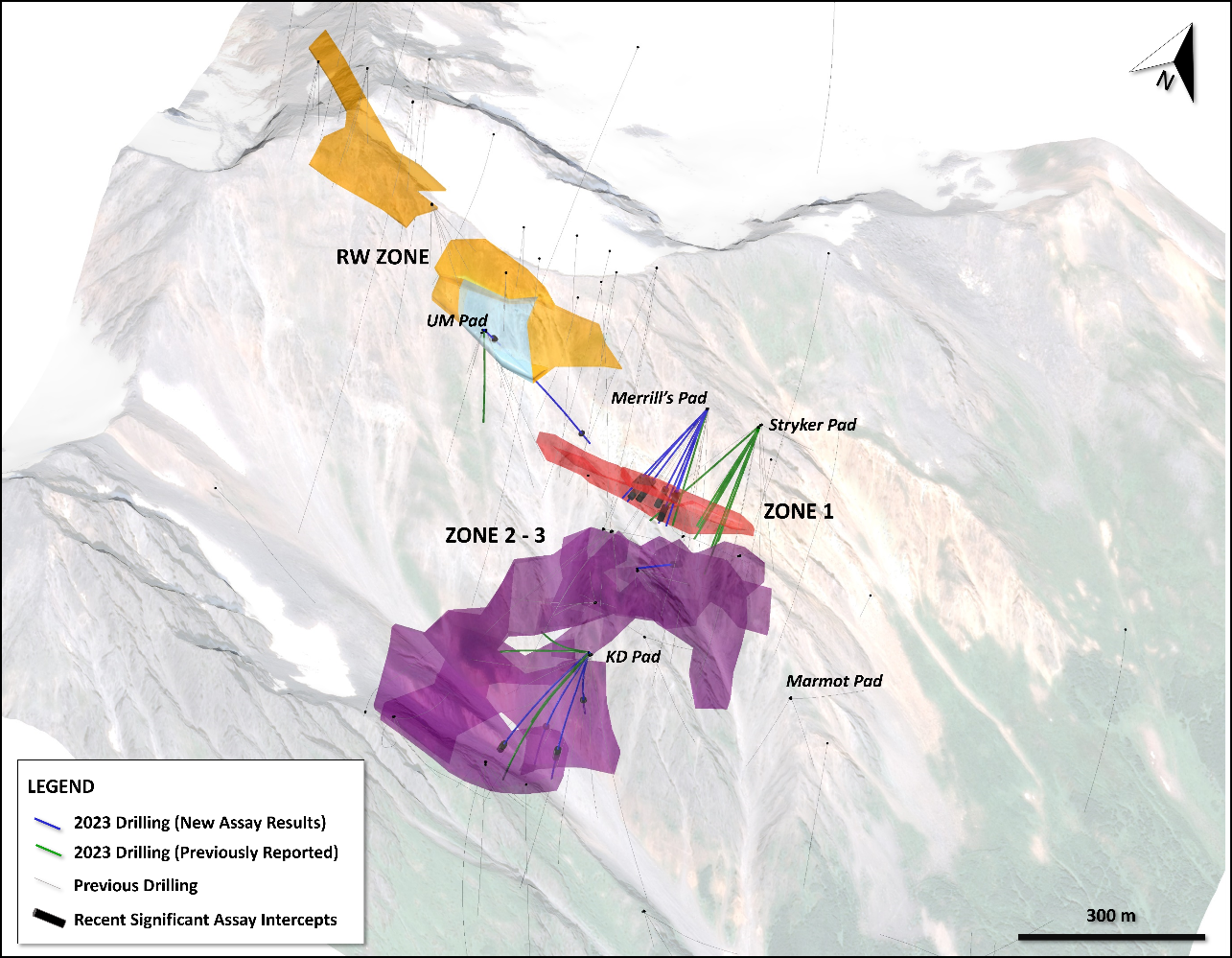

The 2023 diamond drill program successfully targeted high-priority areas in two unique mineralized lenses, Zone 1 and Zone 2-3, which together make up the South Wall Zone of the Palmer deposit (see Figure 1). The Company is incorporating all 2023 results into its 3D geological model to complete interpretation/analysis and target rank drill locations for the 2024 program.

The third and final batch of assay results reported in this release consists of 13 drillholes (seven at Zone 1, five at Zone 2-3, and one geotechnical drill hole at the RW Oxide Zone – see Figures 1-3 and Tables 1-3). See Company news releases dated October 18 and November 14, 2023, for previous 2023 assay results.

Key Takeaways from Latest Assay Results:

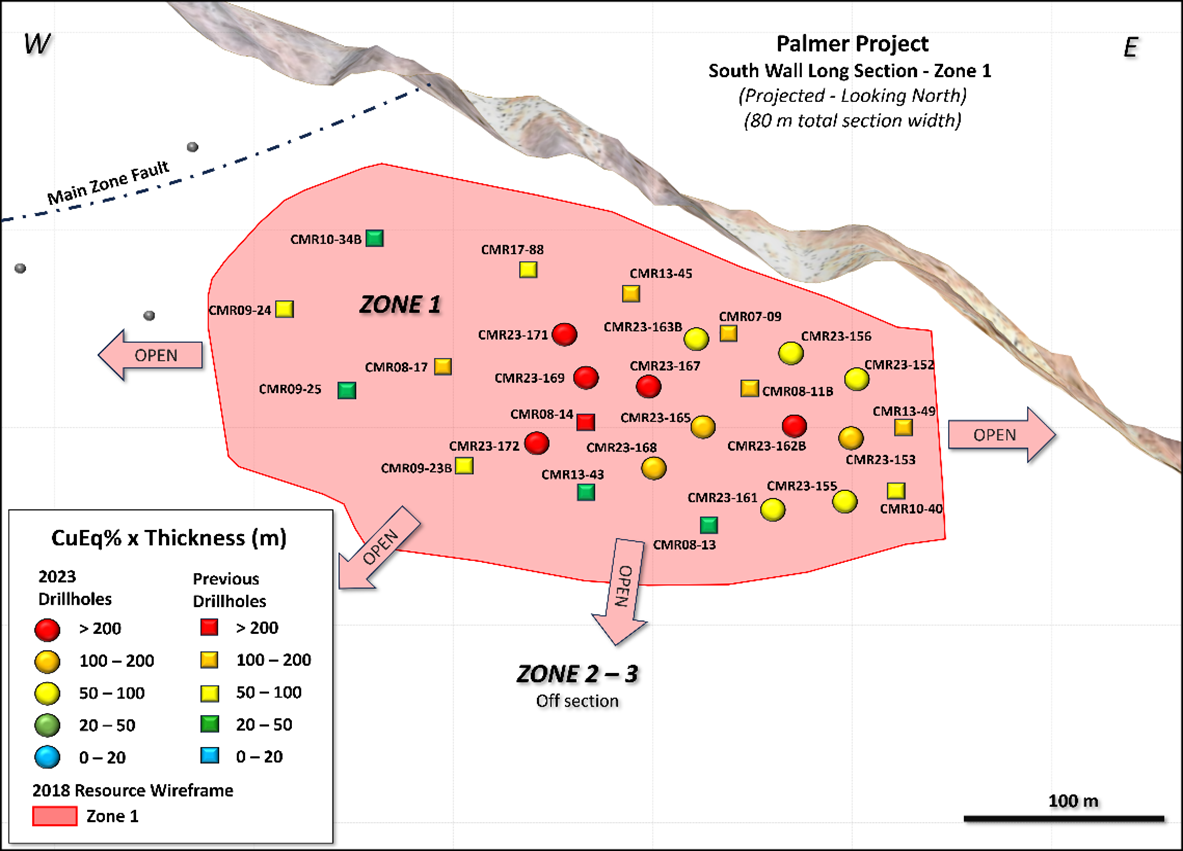

- High-grade copper mineralization with strong metal zoning demonstrated in the core of Zone 1 (see Figure 2 and 3 and Photo 1).

- Cu-Zn mineralization extends beyond the limits of the MRE in Zone 1 highlighting the potential for mineral resource expansion and the discovery of additional lenses downdip and along strike.

- Increased confidence in the current MRE and the 2023 infill drilling provides better methodology for assessing feasibility-level drill space requirements.

Figure 1: Oblique plan view highlighting South Wall Zone 1, South Wall Zone 2-3 and RW Zone

with 2023 drill traces (blue corresponding to newly reported assays).

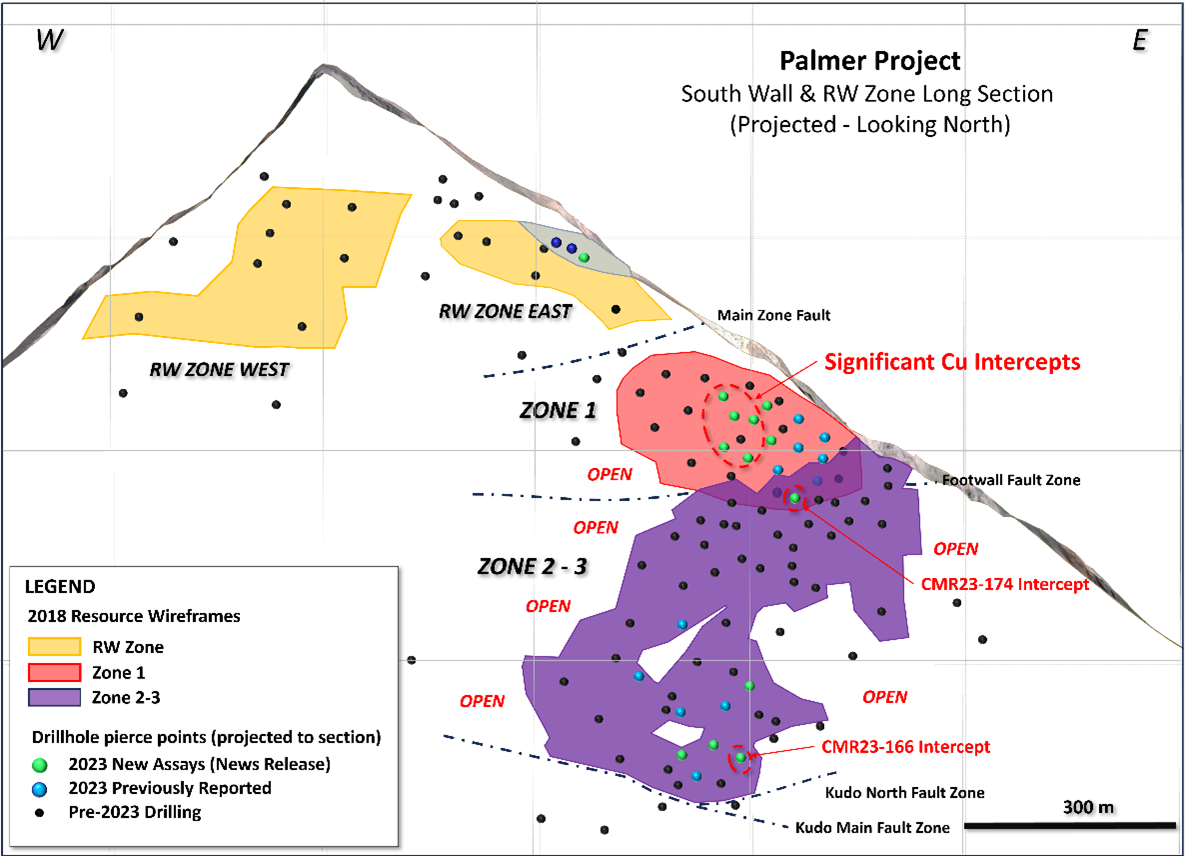

Figure 2: Longitudinal projection of South Wall and RW Zone (looking North) with drillhole pierce points.

Figure 3: Longitudinal projection of Zone 1 (looking north) with 2023 drillhole pierce points (circles) and previous drillhole pierce points (squares) showing Copper Equivalent grade thickness intersections. Note the four new copper-rich drill intersections (red circles) in the core of Zone 1.

Summary of Results and Initial Observations:

- Zone 1: Drill holes CMR23-167, CMR23-169 and CMR23-171/172 stand out for their exceptional copper grades and thicknesses and support an emerging copper-rich core to Zone 1 (see Figures 2 and 3 above).

- Zone 1 : CMR23-172 intersected 43.8 m of 6.54% Cu and 3.15% Zn, extending below the MRE wireframe in an area correlating to the emerging Cu-rich core and that remains open to the west and downdip.

- Zone 1: CMR23-168 (28.4 m of 2.29% Cu and 4.01% Zn) representing a priority step-out target for future drilling as there is limited drilling at >100 m spacing downdip.

- Zone 1: CMR23-161 intersected 18.4 m of 1.6% Cu and 14.7 m of 2.66% Cu and 2.93% Zn, with the bottom of the last intercept extending approximately 20.6 m below the limits of the Zone 1 MRE in an area that remains open to the NE and downdip.

- Zone 2-3: Two distinct sphalerite-chalcopyrite-pyrrhotite-barite massive sulphide horizons have been identified in the drill core. Zone 2-3 remains open for expansion along strike and within the current resource model. The Zone 2-3 mineralization is cut off by the Kudo fault at depth; the interpreted fault offset of the mineralization remains a compelling exploration target.

- RW Oxide Zone: Geotechnical drill hole GT23-025 intersected 1.88% lead, 0.94 g/t Au and 137.4 g/t Ag over 8.1 m. The RW Oxide Zone has limited drilling and is not included in the current MRE. GT23-25 also bottomed in copper mineralization (0.9 m of 2.27% Cu) in an area with limited drilling. This mineralization represents a proximal exploration target for future drill campaigns.

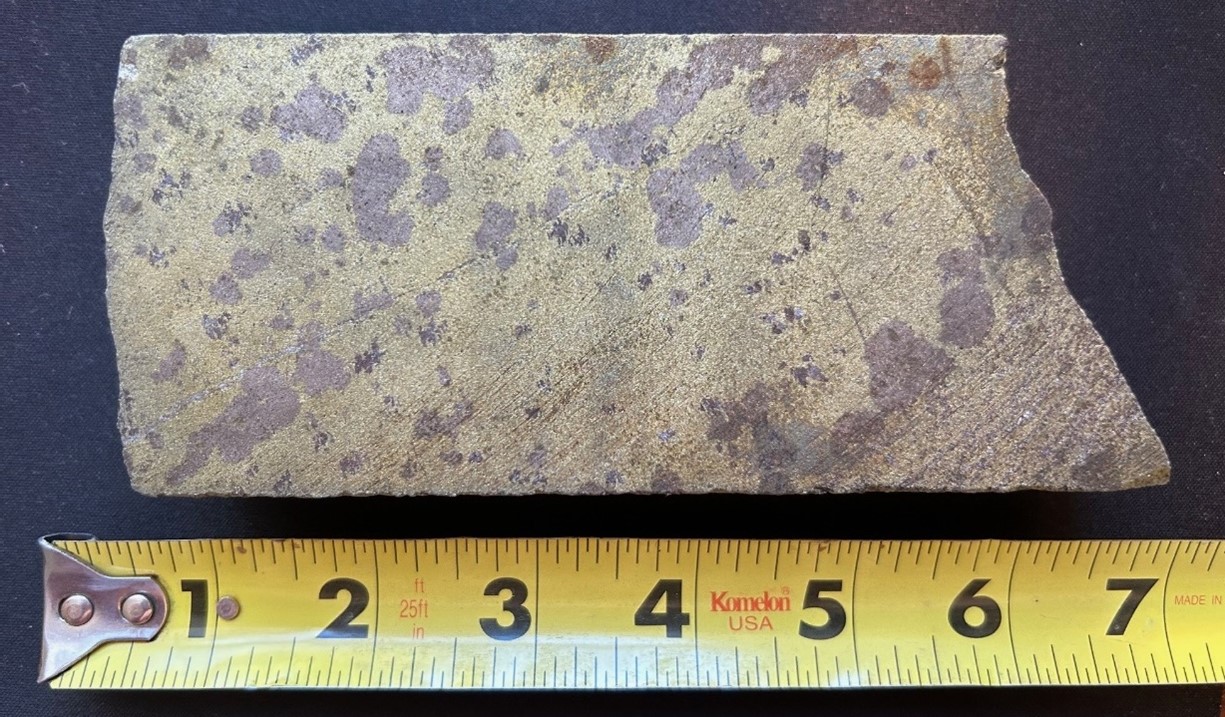

Photo 1: Piece of CMR23-171 split drill core pictured from 15.4 m interval starting from 160.6 m that returned 9.12% Cu, 5.21% Zn, 0.87 g/t Au and 41.93 g/t Ag (11.94% CuEq).

Table 1. Significant Assay Results – South Wall Zone 1

| Zone 1 | From (m) |

To (m) |

Interval (m) |

Cu % |

Zn % |

Pb % |

Au g/t |

Ag g/t |

BaSO 4 % |

CuEQ % |

ZnEQ % |

| CMR23-163 | 154.8 | 158.5 | 3.7 | 1.33 | 18.46 | 0.45 | 0.44 | 50.95 | 32.26 | 9.29 | 23.33 |

| CMR23-163B | 150.9 | 168.2 | 17.3 | 0.49 | 9.40 | 0.15 | 0.32 | 27.18 | 40.02 | 4.60 | 11.56 |

| includes | 150.9 | 158.5 | 7.6 | 0.82 | 14.78 | 0.10 | 0.33 | 25.36 | 49.23 | 7.06 | 17.74 |

| includes | 163.3 | 168.2 | 4.9 | 0.47 | 10.25 | 0.37 | 0.62 | 56.61 | 64.96 | 5.29 | 13.29 |

| CMR23-167 | 161.0 | 198.1 | 37.1 | 4.57 | 8.44 | 0.11 | 0.50 | 29.33 | 8.57 | 8.40 | 21.10 |

| includes | 161.0 | 189.0 | 28.0 | 5.84 | 9.70 | 0.13 | 0.65 | 36.20 | 11.35 | 10.30 | 25.86 |

| includes | 189.0 | 198.1 | 9.1 | 0.66 | 4.58 | 0.04 | 0.05 | 8.21 | 0.00 | 2.57 | 6.45 |

| CMR23-168 | 208.3 | 236.7 | 28.4 | 2.29 | 4.01 | 0.08 | 0.21 | 26.61 | 12.71 | 4.20 | 10.54 |

| includes | 208.3 | 220.2 | 11.9 | 3.31 | 1.08 | 0.01 | 0.22 | 21.57 | 1.57 | 4.02 | 10.08 |

| includes | 220.2 | 236.7 | 16.5 | 1.56 | 6.13 | 0.12 | 0.20 | 30.24 | 20.75 | 4.33 | 10.88 |

| CMR23-169 | 159.4 | 192.6 | 33.2 | 5.48 | 7.22 | 0.13 | 0.64 | 36.78 | 14.77 | 8.95 | 22.47 |

| includes | 159.4 | 168.1 | 8.7 | 1.36 | 12.27 | 0.06 | 0.15 | 12.03 | 22.52 | 6.41 | 16.10 |

| includes | 168.1 | 186.4 | 18.3 | 8.98 | 1.80 | 0.02 | 0.83 | 37.22 | 1.70 | 10.38 | 26.05 |

| includes | 186.4 | 192.6 | 6.2 | 0.94 | 16.41 | 0.55 | 0.78 | 70.21 | 42.46 | 8.29 | 20.81 |

| and | 192.6 | 204.2 | 11.6 | 0.40 | 9.72 | 0.04 | 0.10 | 10.36 | 3.76 | 4.40 | 11.04 |

| includes | 198.9 | 204.2 | 5.3 | 0.38 | 16.03 | 0.03 | 0.06 | 8.01 | 3.60 | 6.86 | 17.22 |

| CMR23-171 | 160.6 | 184.5 | 23.9 | 9.03 | 3.49 | 0.01 | 0.83 | 41.75 | 1.94 | 11.15 | 27.98 |

| includes | 160.6 | 176.0 | 15.4 | 9.12 | 5.21 | 0.01 | 0.87 | 41.93 | 2.91 | 11.94 | 29.97 |

| includes | 176.0 | 184.5 | 8.5 | 8.87 | 0.38 | 0.01 | 0.77 | 41.42 | 0.19 | 9.71 | 24.38 |

| CMR23-172 | 169.6 | 213.4 | 43.8 | 6.54 | 3.15 | 0.01 | 0.42 | 27.97 | 3.72 | 8.22 | 20.63 |

| includes | 175.2 | 181.7 | 6.5 | 6.70 | 5.89 | 0.01 | 0.36 | 32.37 | 0.00 | 9.47 | 23.77 |

| includes | 184.6 | 194.0 | 9.4 | 12.61 | 0.78 | 0.00 | 0.66 | 44.39 | 0.00 | 13.58 | 34.10 |

| includes | 194.0 | 213.4 | 19.4 | 5.73 | 2.18 | 0.01 | 0.46 | 25.53 | 8.40 | 7.01 | 17.61 |

| and | 216.4 | 219.5 | 3.1 | 0.23 | 6.29 | 2.12 | 0.58 | 109.97 | 75.24 | 3.87 | 9.72 |

CMR23-163 abandoned (lost hole) at top of Zone 1; Reported drill intercepts are downhole core lengths with true thickness estimated to be approximately 65-85% of downhole core length.

Copper and Zinc Equivalent Notes:

1. ZnEQ = (Cu/100*2204.6*$lbCu*CuREC) + (Zn/100*2204.6*$lbZn*ZnREC) + (Au/31.1035*$ozAu*AuREC) + (Ag/31.1035*$ozAg*AgREC) / (2204.6/100*$lbZn*ZnREC)

2. CuEQ = (Cu/100*2204.6*$lbCu*CuREC) + (Zn/100*2204.6*$lbZn*ZnREC) + (Au/31.1035*$ozAu*AuREC) + (Ag/31.1035*$ozAg*AgREC) / (2204.6/100*$lbCu*CuREC)

3. Lead and Barite are not included in the CuEq and ZnEq values.

4. Assumed metal prices are US$1.15/lb for zinc (Zn), US$3.00/lb for copper (Cu), US$1250/oz for gold (Au), US$16/oz for silver (Ag) (JDS 2022).

5. Estimated metal recoveries (REC) are 93.1% for zinc, 89.6% for copper, 90.9% for silver and 69.6% for gold as determined from metallurgical locked cycle flotation tests completed in 2018 (JDS 2022).

Table 2. Significant Assay Results – South Wall Zone 2-3

| Zone 2-3 | From | To | Interval | Cu | Zn | Pb | Au | Ag | BaSO 4 | CuEQ | ZnEQ |

| (m) | (m) | (m) | % | % | % | g/t | g/t | % | % | % | |

| CMR23-164 | 417.7 | 421.0 | 3.3 | 1.79 | 3.32 | 0.05 | 0.47 | 44.62 | 8.15 | 3.69 | 9.26 |

| CMR23-166 | 401.1 | 435.9 | 29.5 | 0.07 | 4.09 | 0.10 | 0.05 | 11.41 | 6.92 | 1.82 | 4.56 |

| includes | 410.0 | 425.0 | 15.0 | 0.07 | 5.77 | 0.04 | 0.06 | 12.63 | 6.97 | 2.49 | 6.26 |

| includes | 410.7 | 419.0 | 8.3 | 0.06 | 6.93 | 0.04 | 0.03 | 7.63 | 4.78 | 2.90 | 7.27 |

| CMR23-170 | 483.0 | 485.1 | 2.1 | 0.14 | 2.23 | 1.06 | 0.54 | 107.95 | 0.00 | 2.14 | 5.36 |

| and | 490.6 | 495.9 | 5.3 | 0.24 | 4.72 | 0.43 | 0.17 | 46.20 | 0.00 | 2.57 | 6.45 |

| and | 500.9 | 509.6 | 8.7 | 0.79 | 6.46 | 0.16 | 0.27 | 37.24 | 26.04 | 3.79 | 9.51 |

| includes | 502.9 | 509.6 | 6.7 | 1.01 | 7.88 | 0.19 | 0.31 | 42.47 | 33.82 | 4.63 | 11.62 |

| CMR23-174 | 187.7 | 227.5 | 39.8 | 1.11 | 4.34 | 0.18 | 0.45 | 32.45 | 17.58 | 3.31 | 8.30 |

| includes | 187.7 | 204.9 | 17.2 | 1.05 | 8.86 | 0.39 | 0.94 | 66.24 | 39.13 | 5.54 | 13.91 |

| includes | 188.8 | 196.0 | 7.2 | 0.18 | 8.40 | 0.28 | 0.49 | 81.06 | 50.20 | 4.40 | 11.04 |

| includes | 197.1 | 204.0 | 6.9 | 1.30 | 12.86 | 0.68 | 1.75 | 67.19 | 43.97 | 7.78 | 19.53 |

| includes | 204.9 | 227.5 | 22.6 | 1.15 | 0.90 | 0.01 | 0.09 | 6.73 | 1.17 | 1.60 | 4.03 |

| CMR23-175 | 362.2 | 364.0 | 1.8 | 0.03 | 5.17 | 0.09 | 0.15 | 27.43 | 43.40 | 2.38 | 5.97 |

Drill Intercepts are downhole core lengths. True thickness estimated to be approximately 65-95% of downhole core length.

Table 3. Significant Assay Results – RW Zone

| RW Zone | From (m) |

To (m) |

Interval (m) |

Cu % |

Zn % |

Pb % |

Au g/t |

Ag g/t |

BaSO 4 % |

CuEQ % |

ZnEQ % |

| GT23-025 | 30.5 | 38.6 | 8.1 | 0.06 | 0.04 | 1.88 | 0.94 | 137.42 | 76.35 | 1.60 | 4.02 |

| includes | 33.5 | 38.6 | 5.1 | 0.08 | 0.04 | 2.85 | 1.06 | 162.08 | 76.35 | 1.87 | 4.70 |

| and | 359.9 | 360.8 | 0.9 | 2.27 | 0.04 | 0.00 | 0.21 | 7.40 | 0.00 | 2.44 | 6.14 |

Drill Intercepts are downhole core lengths. True thickness is estimated to be near core length.

Quality Assurance (QA) and Quality Control (QC)

There are strict Quality Assurance and Quality Control (QA/QC) protocols at Palmer covering the planning and placing of drill holes in the field; drilling and retrieving drill core; drill hole surveying; core transport to the Palmer Camp; core logging, sampling and bagging of core for analysis; transport of core from site to ALS Laboratory in North Vancouver, BC for sample preparation and analysis; recording and final statistical vetting of results.

Sampling Procedures – The Company’s QA/QC drill core sample protocol consists of collection of samples over a minimum 0.3 m interval to a maximum 1.5 m interval (depending on the lithology and style of mineralization) over the mineralized portions of the drillhole. The drill core sample is cut in half with a diamond saw, with half of the core placed in individual sealed polyurethane bags and the remaining half securely retained in the original core box for permanent storage. Drill core samples are shipped by transport truck in sealed woven plastic bags to ALS Geochemistry Analytical Lab facility in North Vancouver, BC for sample preparation and analysis. ALS Geochemistry meets all requirements of International Standards ISO/IEC 17025:2017 and ISO 9001:2015. ALS Global operates according to the guidelines set out in ISO/IEC Guide 25.

Gold was determined by fire-assay fusion of a 30 g sub-sample with atomic absorption spectroscopy (AAS). Various metals including silver, gold, copper, lead and zinc were analyzed by inductively-coupled plasma (ICP) atomic emission spectroscopy, following multi-acid digestion. The elements copper, lead and zinc are determined by ore grade assay for samples that return values >10,000 ppm by ICP analysis. Silver is determined by ore-grade assay for samples that return >100 ppm by ICP analysis. Barium (BaO) analysis utilized lithium borate fusion into fused discs for XRF analyses, with BaO converted to BaSO4 (barite) using a conversion factor of BaO x 1.52217. Density measurements were determined at the project site by Constantine personnel on cut core for each assay sample.

The Company maintains a robust QA/QC program that includes the collection and analysis of duplicate samples and the insertion of blanks and standards (certified reference material). In addition, prepared samples, sample replicates, duplicates and internal reference materials are routinely used as part of ALS Geochemistry’s internal quality assurance program.

Qualified Person Statement

The technical information in this news release regarding the Palmer Project has been reviewed and approved by Michael Vande Guchte, P.Geo., VP Exploration for the Palmer Project and a Qualified Person (QP) as defined by National Instrument 43-101, Standards of Disclosure for Mineral Projects.

About American Pacific Mining Corp.

American Pacific Mining Corp. is a precious and base metals explorer and developer focused on opportunities in the Western United States. The Company has two flagship assets: the Palmer Project, a Volcanic Massive Sulphide-Sulphate (VMS) project in Alaska, under joint-venture partnership with Dowa Metals & Mining, owner of Japan’s largest zinc smelter; and the Madison Project, a past-producing copper-gold project in Montana partnered with Kennecott Exploration, a division of the Rio Tinto Group. For the Madison transaction, American Pacific was selected as a finalist in both 2021 and 2022 for ‘Deal of the Year’ at the S&P Global Platts Global Metals Awards, an annual program that recognizes exemplary accomplishments in 16 performance categories. Also, in American Pacific’s asset portfolio are three high-grade, precious metals projects located in key mining districts of Nevada, USA: the Ziggerat Gold project, partnered with Centerra Gold; the Gooseberry Silver-Gold project; and the Tuscarora Gold-Silver project. The Company’s mission is to grow by the drill bit and by acquisition.

On Behalf of the Board of American Pacific Mining Corp.

“Warwick Smith”

CEO & Director

Corporate Office: Suite 910 – 510 Burrard Street Vancouver, BC, V6C 3A8 Canada

Investor Relations Contact:

Kristina Pillon, High Tide Consulting Corp.,

604.908.1695 / Kristina@americanpacific.ca

Media Relations Contact:

Adam Bello, Primoris Group Inc.,

416.489.0092 / media@primorisgroup.com

The CSE has neither approved nor disapproved the contents of this news release. Neither the CSE nor its Regulation Services Provider (as that term is defined in the policies of the CSE) accepts responsibility for the adequacy or accuracy of this release.

JDS (2022 ): 2022 Amended NI 43-101 Technical Report for the Palmer Project prepared by JDS Energy & Mining Inc for Constantine Metal Resources Ltd. The Technical Report is available on the Company’s issuer profile on SEDAR at www.sedar.com

Source: American Pacific Mining Corp.

The post American Pacific Reports Most Significant Copper Drill Intersections To-Date at Its Palmer VMS Project, Including 43.8 Metres of 6.54% and 23.9 Metres of 9.03% Copper appeared first on Financial News Media.