- Cell Q™ integrates the vast majority of typical in-process and release QC assays for cell therapies

- Each Cell Q™ automates the testing of up to 6,000 cell therapy batches per year

- The Cell Q™ includes a set of pre-qualified assays accelerating analytical transfer

- Cell Q™ uses a modular platform that can be expanded to incorporate new instruments providing the flexibility required to meet new IDMO client needs

- High-throughput automation of both manufacturing (Cell Shuttle™) and QC (Cell Q™) enables Cellares IDMO to offer up to 10x higher productivity while reducing batch prices by up to 50% compared with conventional CDMOs

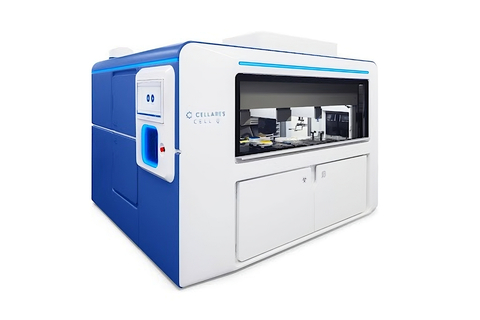

Cellares, the first Integrated Development and Manufacturing Organization (IDMO) dedicated to clinical and industrial-scale cell therapy manufacturing, today unveiled Cell Q™, the first automated quality control (QC) workcell for cell therapy manufacturing. Cell Q™ addresses a critical challenge: the manual, labor-intensive, low-throughput, and expensive nature of cell therapy QC. Exclusive to Cellares’ industry-first IDMO Smart Factories, Cell Q™ will offer a substantial improvement in throughput, cost, and reproducibility compared to existing manual QC methods.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20240418031876/en/

First cGMP Cell Q™ system for automated in-process and release QC of up to 6,000 cell therapy batches per year. (Photo: Business Wire)

As Cellares Cell Shuttles have addressed upstream bottlenecks in cell therapy manufacturing, Cell Q™ resolves the downstream QC capacity challenges. Cell Q™ is engineered to automate the vast majority of cell therapy QC assays for up to 6,000 batches per year. To accelerate analytical method transfer and shorten the time to clinical readout for new IDMO clients, Cell Q™ includes a pre-qualified set of the most common assays. Additionally, each Cell Q™ utilizes a modular platform that can be expanded with new instruments providing the flexibility needed to meet varying IDMO client needs.

Setting a new standard in the industry, Cellares is the only IDMO to offer the same unprecedented capacity for upstream cell therapy manufacturing as well as downstream QC via its South San Francisco Center of Excellence and Smart Factory in Bridgewater, NJ. Additional Smart Factories will be coming soon to the EU and Japan.

“Cell Q™ was designed to match the throughput of our Cell Shuttle™ platform. This enables the Cellares IDMO to offer a real end-to-end solution for our customers, providing 10 times higher capacity and up to 50% lower batch price,” said Fabian Gerlinghaus, CEO of Cellares. “Our proprietary platform technologies support our mission of becoming the de facto standard for cell therapy manufacturing, accelerating access for patients, and meeting the total patient demand for cell therapies globally.”

To learn more about how Cell Q™ enriches Cellares’ IDMO ecosystem and how it alleviates the QC bottleneck for cell therapies, please visit cellares.com/technology.

About Cellares

Cellares is the first Integrated Development and Manufacturing Organization (IDMO) and takes an Industry 4.0 approach to mass manufacturing the living drugs of the 21st century. The company is developing and operating integrated technologies for cell therapy manufacturing to accelerate access to life-saving cell therapies. The company’s Cell Shuttles™ integrates all the technologies required for the entire manufacturing process in a flexible and high-throughput platform that delivers true walk-away, end-to-end automation. Cell Shuttles and Cell Qs will be deployed in Cellares’ Smart Factories around the world to meet total patient demand for cell therapies at global scale. Partnering with Cellares enables academics, biotechs, and pharma companies to accelerate drug development and scale out manufacturing, lower process failure rates, lower manufacturing costs, and meet global patient demand.

The company is headquartered in South San Francisco, California with its commercial-scale IDMO Smart Factory in Bridgewater, New Jersey. The company is backed by world-class investors and has raised over $355 million in financing.

For more information about Cellares, please visit cellares.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240418031876/en/

Contacts

Investors:

ir@cellares.com

Media:

pr@cellares.com