VANCOUVER, BC / ACCESSWIRE / March 15, 2022 / EnviroMetal Technologies Inc. ("EnviroMetal" or the "Company") (CSE:ETI; OTCQX:EVLLF; FSE:7N2), is pleased to announce positive results from the first phase of test work conducted on behalf of Group 11 Technologies Inc. ("Group 11").

EnviroMetal and Group 11 are developing an environmentally friendly processes for the in-situ recovery ("ISR") of gold and other metals. As part of an ongoing collaboration with Group 11, EnviroMetal conducted an initial 6-month research program using its proprietary and environmentally friendly gold recovery technology on core samples taken from the Rattlesnake Hills Project ("Rattlesnake"). Rattlesnake is a district scale gold exploration property located in Wyoming which Group 11 has optioned for the testing and development of ISR for gold. The core samples used in the first phase of test work were selected to cover a maximum range of gold bearing rock types and gold grades present at Rattlesnake.

Using EnviroMetal's proprietary solution, recovery tests on uncrushed half-core samples demonstrated gold recoveries ranging from 15.9% to 77.5%, averaging 48.2% with most results achieved in less than 30 days. Comparative bottle roll tests conducted on crushed and ground material returned gold recoveries ranging from 38.3% to 89.5%, averaging 61.4%.

Duane Nelson, EnviroMetal CEO, comments, "These test results are very encouraging. Our initial research into this application for our chemistry demonstrates that ISR applications hold real potential, and these results verify thoseearly indications. We are cautiously optimistic that our reagent chemistry, combined with Group 11's notable expertise in ISR process technologies, may deliver a world-changing technology for the gold mining industry. We look forward to the ongoing collaboration with Group 11 on the path toward commercialization of this truly disruptive innovation for the gold mining industry."

Dr. Dennis Stover, Group 11's Chief Technical Officer and co-discoverer of the in-situ recovery process for use in uranium mining said: "Group 11 is very pleased with the initial tests which showed strong results to extract gold from the existing core sample with an environmentally friendly solvent. This first step will provide the basis for future tests to be conducted on the use of the lixiviant in combination with in-situ recovery technology. Group 11 is working to create new environmentally friendly options to extract gold and other metals through less invasive ISR extraction which is widely use in the uranium industry."

UNCRUSHED SAMPLE TESTING

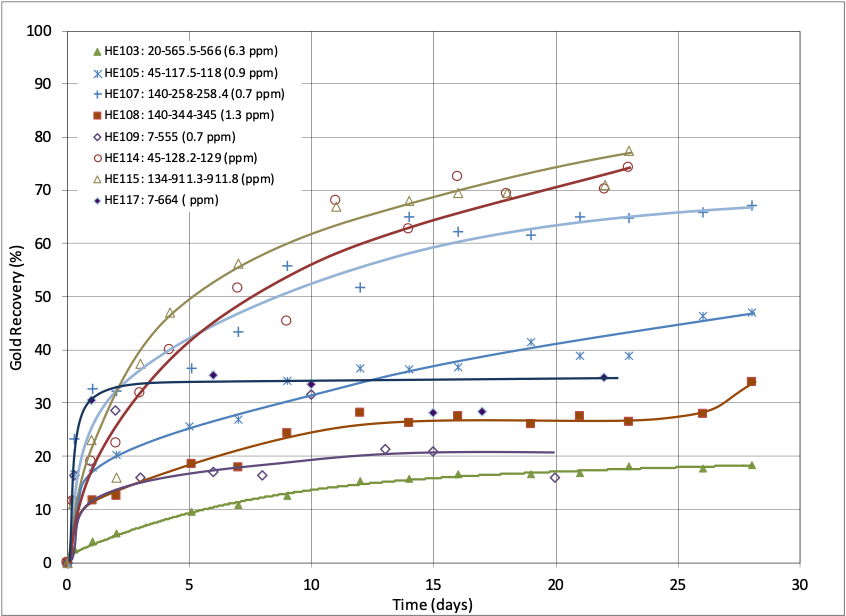

The half core samples were leached whole and uncrushed in the Company's lixiviant at 28% - 45% pulp density for 22 to 92 days to investigate gold recovery for in-situ recovery application. Gold recoveries ranged from 15.9% to 77.5%, averaging 48.2%. These samples were tested whole without crushing to emulate expected results more closely from an ISR environment.

Select Sample Results of Uncrushed Half-Core Leach Test

Au Grade (g/t) | ||||||

Test Number | Cal Head | Pulp Density % | Leach Time (days) | Au Rec. (%) | ||

HE103 | 6.33 | 40.6 | 28.1 | 18.4 | ||

HE105 | 0.90 | 40.4 | 28.1 | 47.0 | ||

HE107 | 0.73 | 39.3 | 28.1 | 67.1 | ||

HE108 | 1.31 | 40.7 | 28.1 | 34.1 | ||

HE115 | 2.30 | 38.5 | 23.0 | 77.5 | ||

Recovery Curve of Uncrushed Half-Core Leach Test vs. Time:

BOTTLE ROLL TESTING

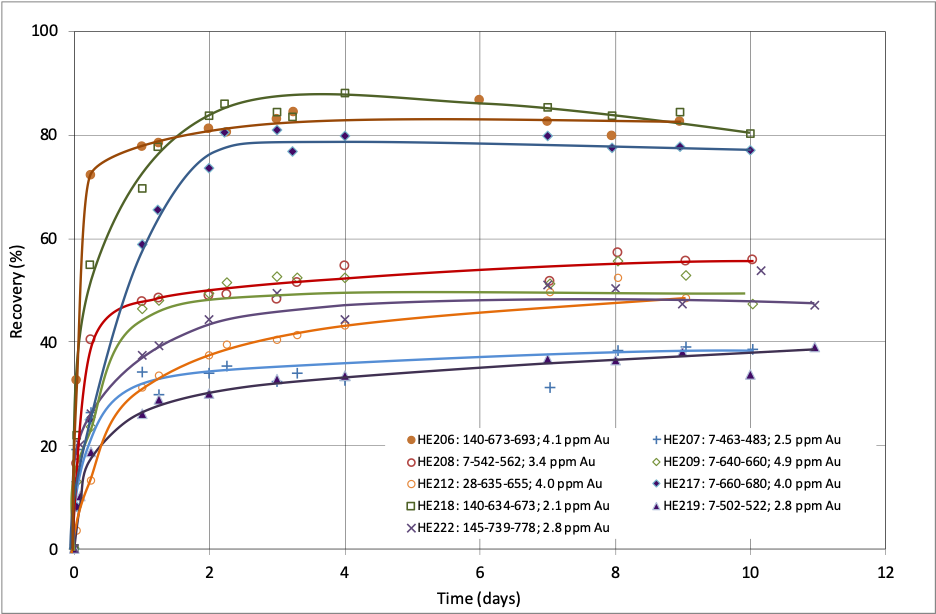

The rock samples were crushed to -2.5 mm and tested via bottle roll methodology with the Company's lixiviant at 30% pulp density for 9 to 28 days at a neutral pH. Gold recoveries ranged from 38.3% to 89.5%, averaging 61.4%. Leaching with the bottle roll on crushed material provided faster kinetics and higher recoveries, as would be expected, due to the increased surface area exposed to the lixiviant.

Select Bottle Roll Test Results on Minus 2.5mm Crushed Composite Core

Au Grade (g/t) | ||||||

Test Number | Cal Head | Assayed | Leach Time (days) | Au Rec. (%) | ||

HE201 | 8.96 | 8.84 | 9 | 54.3 | ||

HE202 | 14.21 | 14.03 | 9 | 62.9 | ||

HE203 | 7.10 | 7.62 | 9 | 75.1 | ||

HE204 | 1.46 | 1.57 | 9 | 83.6 | ||

HE205 | 8.63 | 6.39 | 9 | 48.1 | ||

HE206 | 4.10 | 3.65 | 9 | 82.5 | ||

HE207 HE216 | 2.49 0.87 | 2.48 0.72 | 10 10 | 38.6 89.5 | ||

Recovery Curve of Bottle Roll Test with Minus 2.5mm Crushed Material

Although not directly comparable due to significantly different testing parameters, according to the feedback the Company has received from Group 11, these bottle roll test results compare favorably with cyanide-based bottle roll results from historic testing conducted in 2009 by Resource Development Inc. (RDI) for the Rattlesnake Project. The RDI testing utilized cyanide with 1g/l of NaCN, a pH of 11, 40% solids, 72 hour leaching time and a very fine grain size of 80% less than .074mm. Gold recoveries ranged from 13.7% to 65.4%, averaging 43.4% from 15 composite drill core samples.

QA/QC Protocol

Splits of the crushed head samples and leach tails from the 22 bottle roll tests as well as the tails from the 17 half core leach tests were analyzed by MSALABS, an independent lab based in Langley, British Columbia.

About Group 11 Technologies Inc.

Group 11 is a private US-based company committed to the development and application of environmentally and socially responsible precious metals mineral extraction. The combination of non- invasive extraction technology and environmentally friendly processes to recover gold and other metals provides an alternate solution to conventional open pit and underground mineral extraction. The goal of advancing sustainable extraction considers growing concerns surrounding water use and discharge, carbon footprint, energy consumption, community stakeholders and workplace safety while addressing a growing global need for metals in our daily lives. Group 11 is owned in part by EnviroMetal Technologies Inc.

About EnviroMetal Technologies Inc.

EnviroMetal Technologies is engaged in the development and commercialization of environmentally friendly formulas and technologies for the treatment of materials in the primary and secondary metals industries. Using its proprietary non-cyanide, water-based, neutral pH treatment process EnviroMetal extracts precious and non-precious metals from ores, concentrates, and electronic waste. Backed by the momentum of a first-class staff of scientists and engineers, a myriad of individual tests and assays, independent validations, and tens of thousands of hours in research and development, EnviroMetal's technology is emerging as a potential new eco-friendly standard for the hydrometallurgical extraction of precious metals in both the mining and E-Waste industries. For more information, please visit www.EnviroMetal.com

Forward-Looking Statements

This News Release contains "forward-looking information" and "forward-looking statements" within the meaning of applicable Canadian and the United States securities legislation. Statements contained herein that are not based on historical or current fact, including, without limitation, statements containing the words "anticipates," "believes," "may," "continues," "estimates," "expects," and "will" and words of similar import, constitute "forward-looking statements" within the meaning of the U.S. Private Securities Litigation Reform Act of 1995.

Forward-looking information may include, but is not limited to, information with respect to the term of the Interim Injunction and the receipt of the written decision in respect thereof. Wherever possible, words such as "plans", "expects", "projects", "assumes", "budget", "strategy", "scheduled", "estimates", "forecasts", "anticipates", "believes", "intends", "targets" and similar expressions or statements that certain actions, events or results "may", "could", "would", "might" or "will" be taken, occur or be achieved, or the negative forms of any of these terms and similar expressions, have been used to identify forward-looking statements and information. Statements concerning future revenue or earnings estimates may also be deemed to constitute forward-looking information. Any statements that express or involve discussions with respect to predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance are not statements of historical fact and may be forward-looking information. Forward-looking information is subject to a variety of known and unknown risks, uncertainties and other factors that could cause actual events or results to differ from those expressed or implied by the forward-looking information. Forward-looking information is based on the expectations and opinions of EnviroLeach's management on the date the statements are made. The assumptions used in the preparation of such statements, although considered reasonable at the time of preparation, may prove to be imprecise. We do not assume any obligation to update forward-looking information, whether as a result of new information, future events or otherwise, other than as required by applicable law. For the reasons set forth above, prospective investors should not place undue reliance on forward-looking information.

The CSE has not approved or disapproved of the information contained herein.

Contact Information:

Jason Leikam

VP Business Development

EnviroMetal Technologies Inc.

info@Envirometal.com

(604) 428-2400 x 104

SOURCE: EnviroMetal Technologies Inc

View source version on accesswire.com:

https://www.accesswire.com/693088/EnviroMetal-Reports-Positive-Results-from-Group-11s-First-Phase-In-Situ-Research-Program